Imikhiqizo

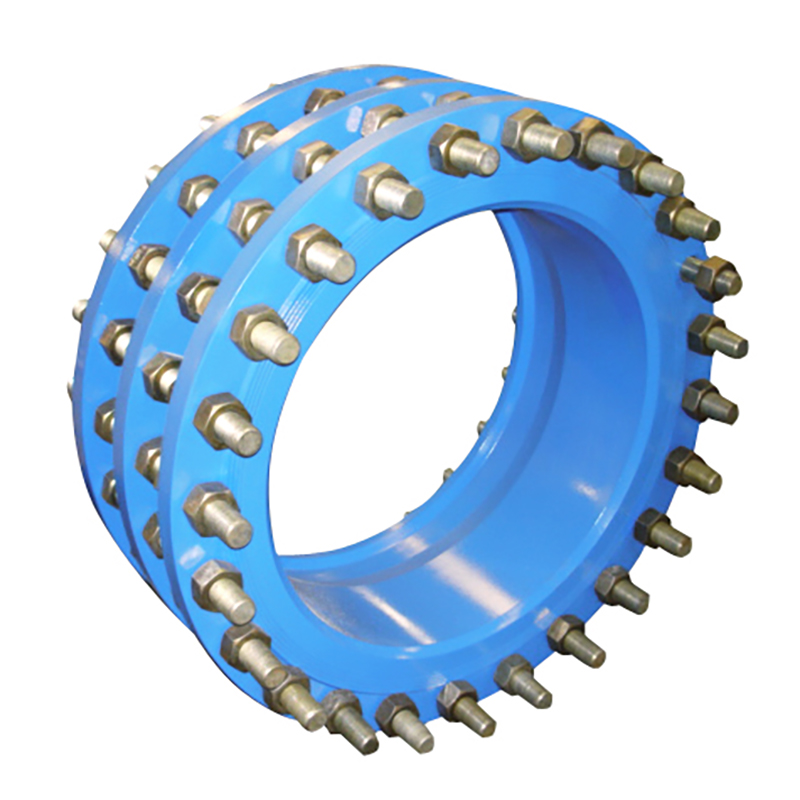

Ukudiliza amalunga

Incazelo emfushane:

Ibanga losayizi: DN50 kuya ku-DN4000

Ibanga lokucindezela: PN6, PN10, PN16, PN25, PN40 ne-PN64, Ikilasi 150 & Ikilasi 300, noma ingcindezi ephezulu kakhulu ezoklanywa ngokuqondile.

Indawo efanelekile: amanzi, amanzi olwandle, igesi, uwoyela, uketshezi lwe-ow-corrosive, nokunye.

Izinga lokushisa elifanele.: -20 kuya ku-100 ℃ degree

I-Flange ne-drilling acc.to : ISO7005-2,EN1092-2/-1, ANSI B16,5,ANSI B16.47, AWWA C207 nokunye.

I-Coating: i-fusion eboshiwe ye-epoxy, imiz.ubukhulu - 300 microns

I-Pressure test acc.to: EN12266-1, ISO5208

Izinga lokuvuza: Ikilasi A (Ukuvuza kweZero) kuzo zombili izinhlangothi, ukuhlolwa okungu-100% ngaphambi kokulethwa

Incazelo Yomkhiqizo

Uhlu lwezingxenye eziyinhloko:

I-Flange spigot: i-ductile cast iron, GGG40/50, QT450-10, carbon steel, insimbi engagqwali nokunye.

Umzimba we-Flange: i-ductile cast iron, GGG40/50, QT450-10, carbon steel, insimbi engagqwali nokunye.

Isigcini: i-ductile cast iron, GGG40/50, QT450-10, carbon steel, insimbi engagqwali nokunye.

I-Gasket: NBR/EPDM

Tie rods: steel galvanized, grade 4.8,6.8 noma 8.8, noma nge-Dacroment, SS304, SS316, duplex steel nezinye insimbi engagqwali, enye impahla ethile etholakalayo njengesicelo.

I-Coating: i-fusion eboshiwe ye-epoxy, imiz.ubukhulu - 300 microns

Iphakheji: amakesi e-plywood, alungele ukuthunyelwa ngolwandle, ngomoya, noma ngesitimela, amaphalethi amasayizi angaphezu kwavamile.

Incazelo yokukhiqiza:

1.Qeda uxhumano: ama-flange amabili

2.Ubude obuphelele bokuxhumana bungalungiswa, kukhona inani elithile lokunwetshwa.Ngokuvamile, ukunwetshwa okuphezulu komklamo kungu-50mm.

I-3.Bangakwazi ukufaka esikhundleni sepayipi eqondile ye-flanges ephindwe kabili, ngesikhathi sokulungiswa, ukulungisa ukufakwa kwamapayipi okonakalisiwe kwasekuqaleni noma ukuxhuma amapayipi amasha, futhi izici zobude obulungiswayo zenza kube lula kakhulu kunamapayipi e-flange ekusetshenzisweni kokwakhiwa nokufakwa.Ngokuvamile zixhunywe eduze kwe-valve.

4.Amabhawodi * amantongomane angasetshenziswa ngokuqondile ukuxhuma i-flange epayipini.

5.Ngasikhathi sinye, singaphinde sinikeze isethi yesigamu yama-bolts, okungukuthi, ama-bolts anezimbobo ze-bolt ezingu-50%.

Kungokwesakhiwo sethu esisha, esinciphisa isisindo kanye nezindleko, zinokuncintisana kakhulu.

Umsebenzi nomgomo:

Umsebenzi wedivaysi ye-telescopic ukuxhuma amaphampu, ama-valve namapayipi, nokwenza isinxephezelo ngawo.

Isinxephezelo sepayipi singanwetshwa nge-axially phakathi kwebanga elithile, futhi singaphinda sinqobe i-offset ebangelwa i-axis yamapayipi ehlukene ku-Engeli ethile.

Isiza kakhulu ukufakwa nokususwa kwama-valve namapayipi.Inganwetshwa ngokukhululekile phakathi kwezandiso zamapayipi ezivunyelwe.Uma idlula ukunwetshwa kwayo, izosebenzisa imingcele ukuze kuqinisekiswe ukusebenza okuphephile kwepayipi.

Idivayisi ye-telescopic inomphumela wokugudluza izinkomba eziningi ngesikhathi sokusebenza kwepayipi.Amapayipi asebenza ngenxa yokwanda nokufinyela okushisayo, futhi ukuncipha kanye namandla oqweqwe kukhiqiza imiphumela ebalulekile yesinxephezelo sokukala.

Ukufakwa:

I-Dismantling Joint ihlanganiswa yizinto ezihlanganisayo eziphindwe kabili, okwenza isenzo sokuhoxisa phakathi kwe-spigot ene-flanged ne-adaptha ye-flange.

Yakhelwe ukuhlinzeka ngokulungiswa kwe-longitudinal (kufika ku-50mm) kumasistimu ane-flanged.Inikeza indlela elula yokufakwa nokususwa kwemikhiqizo e-flanged ngokulungisa ibanga phakathi kwemikhiqizo emibili e-flanged nokuphenduka.

Ukufakwa nakho kulula futhi sebenzisa kuphela isikrufu se-torque ukuze uqinise insimbi enamandla amakhulu noma amabhawodi okuxhuma ensimbi engagqwali.

Ingahlakazwa ngokushesha futhi ilungele kakhulu ukulungiswa nokugcinwa kwama-valve, amaphampu noma izinsimbi.

Kwenza kube lula isikhathi esidingekayo sokunakekelwa nokulungiswa kwamapayipi amanzi esikhathini esizayo futhi kunciphisa isikhathi sokuphumula kuwo wonke umsebenzi wamapayipi.

Izinzuzo:

1, Ingavimbela umthelela wokudlidliza epayipini.Ngenxa yokuthi kunenani elithile lokugudluzwa kudivayisi ye-telescopic, ingaba nomthelela wokuvikela epayipini ngesikhathi sokudlidliza.

I-2, ivumela ukufakwa nokushintshwa kwepompo nama-valve.Kunesikhawu phakathi kwendikimba yedivayisi yokunweba kanye nedivayisi yokunweba, engalungiswa kalula ngokuya ngosayizi wokufaka kunqubo yokufaka nokulungisa.

3, Inomphumela othile we-buffer ku-axial, transverse kanye ne-angular thermal deformation.

Sekukonke, ijoyinti lokunweba linikeza insizakalo enkulu yokufakwa nokushintshwa kwamapayipi amanzi ahlukahlukene kanye namapayipi okukhipha amanzi, imibhoshongo yamanzi, amaphampu, amamitha amanzi namavalvu.

Umkhiqizo unomphumela omningi wokulawula ekwandeni nasekufinyezweni okubangelwa umehluko wezinga lokushisa ekudlulisweni kwamapayipi amade.

Bhalisa Manje

Izinga elingenakuqhathaniswa lekhwalithi kanye nensizakaloSihlinzeka ngezinsizakalo ezenziwe ngokwezifiso zamaqembu nabantu ngabanyeSithuthukisa isevisi yethu ngokuqinisekisa inani eliphansi kakhulu.